Production Escalation

Slub Yarn manufacturing has commenced for markets of Denim and Shirting to produce 2 tons /day. 5 ton capacity of TFO doubling has been added to produce ply yarns ranging from NE 10/2 to NE 20/2 in carded and combed segments. The new Compact Yarn system integrated delivers @ 5 tons/day.

Precision Machinery

Foraying into open ended spinning with World’s best machinery from Truetzchler, Saurer, Reiter and Luwa aiming to achieve 20 tons of production per day from this facility alone.

Passion for Perfection

Proud to achieve GOTS Certification for all products from Control Union (Switzerland). Organic Yarn of every kind is being produced to retain a brand of international quality fabric manufacturers in domestic and export markets.

Green Technology

Green Technology Greener Earth - JTPL has taken up 10 MW Wind Projects under captive utilization model. The power generated from wind turbines will offset the conventional energy utilized at JTPL factory in Narasaraopet.

The Company

Jyothirmaye Textiles Pvt. Ltd. is identified as an eminent brand in cotton yarn making in the national and international markets. Though a young entry in the foray, JTPL has carved its niche for its quality yarn production and supply. It has evolved as a company with strong infrastructural and operational base for production and supply of excellent quality knitting and weaving yarns to prominent national and international textile and weaving industries.

Established in 2011, Jyothirmaye Textiles is thriving under the able and experienced management, to flourish as a US$33 million (`200 crore) Company, with perfection-oriented production processes, strong customer centric approach and practices.

Read More

THE JOURNEY

Jyothirmaye group was envisioned and fostered by visionary entrepreneurs Shri Danda Bramhanandam, Shri Ravela Satyanarayana and Shri Nalabothu Venkat Rao.

The Managing Director Shri Danda Prasad as a protégé of Sri Danda Brahmanandam, has refined his entrepreneurial skills. He has further enriched his perspective with education and work experience in the US. He has taken the Jyothirmaye Textiles and its products to accomplish various benchmarks and milestones in last five years.

- 2011: Commissioned 20,160 Spindles with state of the art machinery to produce 30s to 40s Cotton Karded and Combed Weaving Counts at factory premises

- 2015: Expanded 18,720 Spindles with latest technologies to produce 10s to 20s Cotton Karded Weaving Counts at factory premises

- 2016: 6 MW Wind Power Commissioned in Kurnool District for captive consumption

- 2017: 4 MW Wind Power added to existing capacity in Ananthpur District for captive consumption

- 2017: Introduced Compact, Slub, and Doubled yarns

- 2018: Commissioned Open End Spinning with modern machinery at factory premises

- 2018: Expanded Combed and Compact capacities

Today, JTPL profiles thus:

- Advanced technology incorporated to produce world class cotton yarns that address all end applications

- Most sophisticated and precision refined USTER testing equipment to sustain USTER 5% standards

- 38880 spindles and 2688 rotors with production capacity of 12000 mt. per annum and poised to achieve spiraling highs in capacity building and production

- 420,000 sft. of manufacturing area equipped with technology and precision driven infrastructure

To endeavor and meet the increasing challenge of supplying quality yarns consistently as desired by customers of varied requirements based on highly variable raw material as cotton.

To be identified as a stellar group by all stake holders: Customers, Employees, Investors and Society at large.

Passion driven by a personal commitment to make a difference. Commitment to excellence assured by the highest ethical, quality, operational performance and scientific standards.

Infrastructure

Company

The Company takes pride in being one of the eminent manufacturers and suppliers of high performance knitting and weaving cotton yarns with the Machinery sourced from world's acclaimed precision machinery manufactures. To accomplish this, best infrastructure has been created with eco-friendly buildings surrounded by lush greenery and zero emission standards are maintained.

JTPL has also created a stringent code of conduct to meticulously meet the delivery targets within the country and abroad. Entire operations are strategically located where raw cotton sourcing is consistent in terms of quality and measure. The strategic location enables the Company to ship the goods to any textile manufacturing clusters in India and abroad due to its vicinity to ports.

Plant and Machines

The Spinning Process goes through quality checks at every stage before materials go for next operations. Every quality inspection has been standardized and matches USTER-5% Standards. This includes Sliver Neps / Short fibres / Evenness / Trash levels etc.

Yarn Parameters of Jyothirmaye Textiles match the best standards and all the characteristics of Yarn like Evenness, Imperfections, Higher Sensitive Faults, Classmat Faults, Yarn Strength and Bundle Strength match USTER - 5%.

Machinery (Unit - I & Unit - II)Infrastructure at Glance

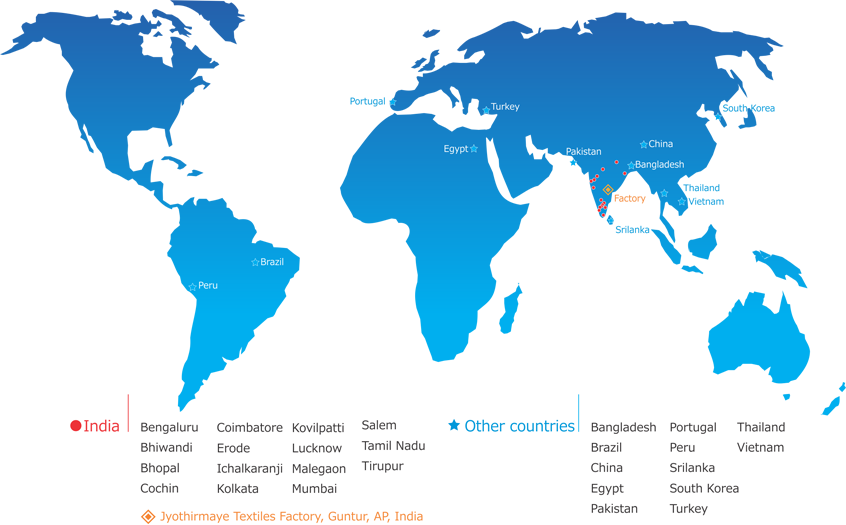

Connecting the dots on the globe

Jyothirmaye Textiles has carved a niche for itself in Textile Industry across India. The Company is also adding its share to the country`s exports. The products of Jyothirmaye Textiles are being exported to various destinations across the world through merchant exports. The geographical location of the mill in the proximity of commercial ports such as Chennai, Krishnapatnam and Visakhapatnam gives an edge to the shipment logistics.

where goods can be delivered within shipment schedule to the satisfaction of International Buyers. Over the years, JTPL has acquired a creditable reputation and trust in the textile echelons. Its strong domestic and export consumer base and global presence bear testimony to the fact.

Our Achievments

SPINDLES

MT PRODUCTION CAPACITY per annum

SFT MANUFACTURING AREA

Adopting Green Practices for Clean Energy

Wind represents a clean, entirely renewable and potentially unending source of energy. It is one of the fastest growing sources of power generation in India today. Wind farms releases negligible levels of carbon dioxide. Power generated from wind turbines augment energy that is otherwise generated using carbon intensive technologies and therefore helps reduce carbon emissions. Each Wind Generating Turbine in its life span of 25 Yrs will help reduce 5.6L Tonnes of Co2 and 16Sq Km of forest area. JTPL endeavors to be a responsible business player, playing an important role in the community beyond its role in the Textile industry.

In an endeavor to be the responsible business player, JTPL has taken up 10 MW Wind Projects under captive utilization model. The power generated from wind turbines will offset the conventional energy utilized at JTPL factory in Narasaraopet. The 6MW Power Project at CKM Palli, Kurnool Dt of AP with capacity 3 x 2MW Inox Make WTGs with 93Mts Rotor Dia & 80Mts Height and the total generation of 1.35Cr KW Units per annum. Similarly the 4MW Wind Project at Tallimadugula with capacity of 2x 2MW, Inox Make WTGs with 100Mts Rotor dia & 92Mts height with total generation of 90L KW Units per annum.

Our Esteemed Clients